Chiral Techniques

Preparative Chromatography

Eliminating impurities in compounds destined for use in pharmaceutical, veterinary, and agrochemical products is essential to ensure product quality and integrity. Daicel Chiral Technologies provides an array of chiral selectors to address your preparative chromatography needs.

Wide range of options

Daicel Chiral Technologies offers a broad range of solutions to meet your preparative and semi-preparative separation needs.

- Diverse selectors—with extensive selectivity possible from coated and immobilized polysaccharide to zwitterionic and anion exchange chiral selectors.

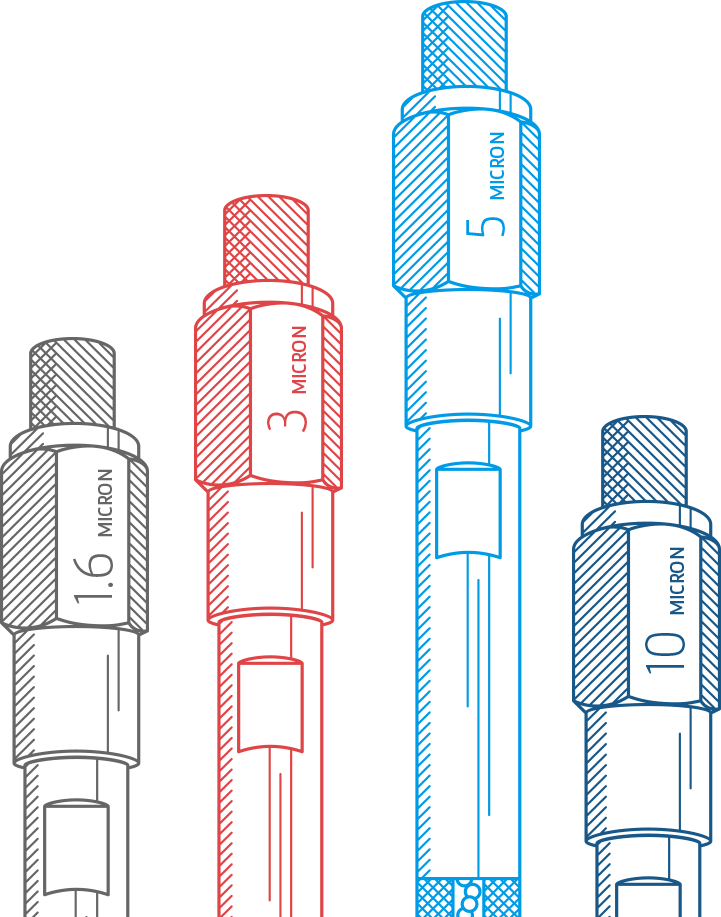

- Broad size range—from 5 micron to 10 micron to 20 micron and columns ranging from 10mm i.d. to 100mm i.d.

Bulk chiral stationary phases

Daicel Chiral Technologies also provides bulk chiral stationary phases derived from polysaccharides and other materials to meet your specific preparative separation needs. Bulk chiral stationary phases are available in 100-gram to multi-kilogram quantities.

Separation services

Rely on Daicel Chiral Technologies for rapid, cost-effective separations of compounds to satisfy your development and production requirements. We perform separations in our state-of-the-art facilities at scales ranging from milligrams to hundreds of kilograms to metric tons.